100% True Cold-Pressed Juice

Pure, Honest, Always Fresh.

At Re.juve,

We’re more than just a juice brand—we’re your daily partner in living well. Every bottle we make is a promise: to deliver the freshest, most natural cold-pressed juices crafted from real fruits and vegetables, with no shortcuts.

Made for Every Lifestyle

Whether you’re resetting with a detox, looking for a daily boost, or simply enjoying delicious nutrition, Re.juve fits right into your routine. Each juice is cold pressed to preserve the full goodness of nature. Without preservatives, sweeteners, or anything artificial.

Introducing

2 Step Cold-Pressured™

Re.juve's juices are made with our exclusive 2-Step Cold-Pressured™ process. This proprietary technology is what sets us apart from other cold-pressed juice brands in Singapore.

Step 1: Cold-Pressed

We gently extract juice from fresh fruits and vegetables without heat. This protects the flavour, nutrients, and natural enzymes.

Step 2: High-Pressure Processing (HPP)

Next, each sealed bottle undergoes cold water pressure at 4°C. This step naturally removes harmful bacteria, extends shelf life, and keeps the juice safe—without using heat, preservatives, or chemicals.

This two-step process means you get the best of both worlds: Maximum Nutrition & Natural Safety, with a clean, fresh taste in every bottle.

Why it Matters

• Retains more nutrients

• Naturally safe & hygienic

• No preservatives or additives

• Fresher for longer

• Used in every Re.juve product

The Science of Freshness

From sourcing to bottling, our process is designed to protect what's good. High-Pressure Processing (HPP) eliminates harmful bacteria while keeping nutrients and flavours intact. No pasteurisation. No shortcuts. Just science-backed freshness.

End-to-End Cold Chain

Freshness isn’t just a result — it’s a system. We maintain a full cold chain from regional farms to our juicing facility, and right throughto delivery. That’s how we preserve quality without freezing or heat treatments.

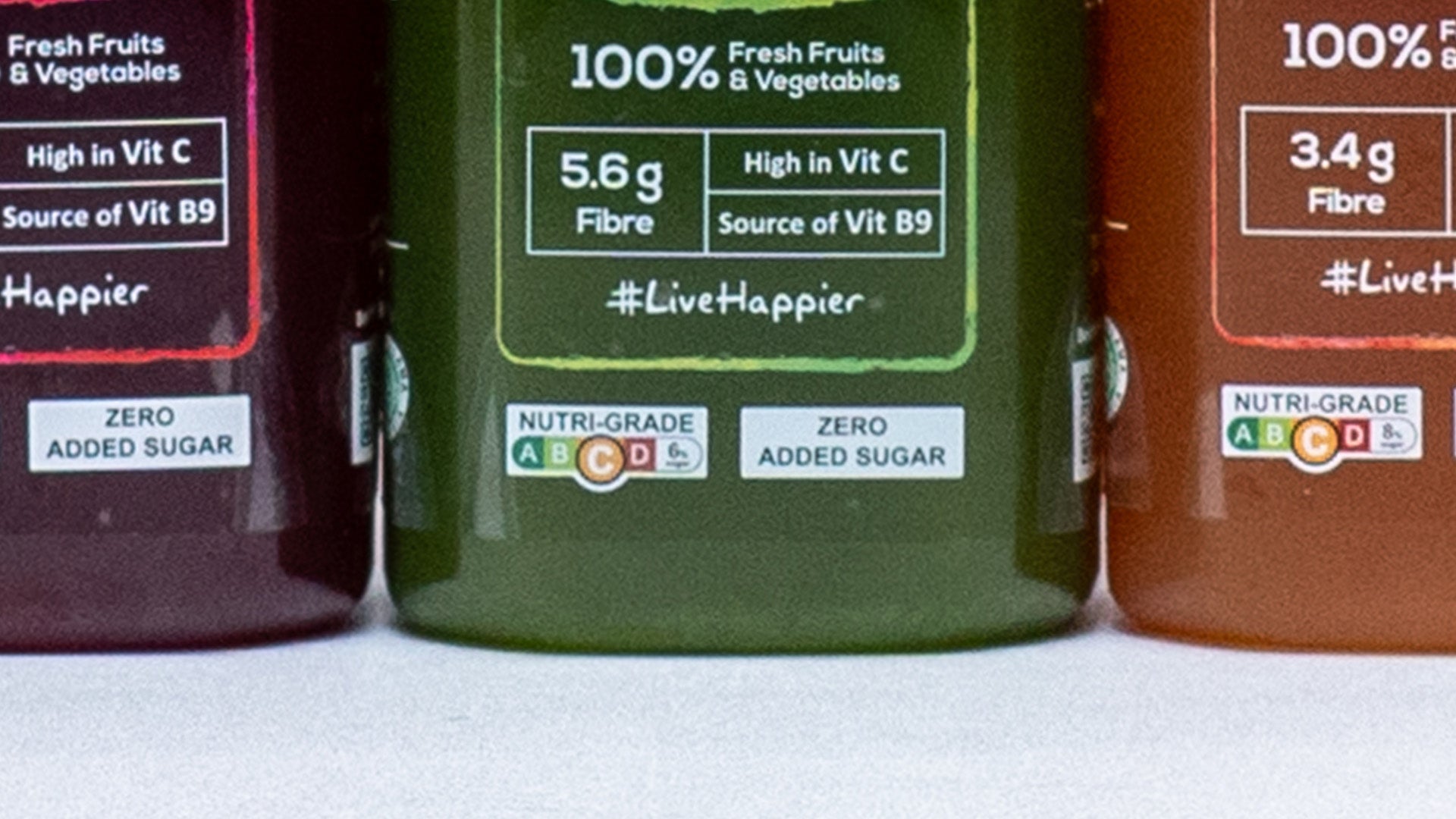

Clean Labels, Full Transparency

We believe you deserve to know what you're drinking. Every Re.juve bottle includes complete nutritional information and fully complies with Singapore’s Nutri-Grade labelling system.